ZT hom Casing Drilling ntsis, Reaming tho txawv taub hau

Product Description

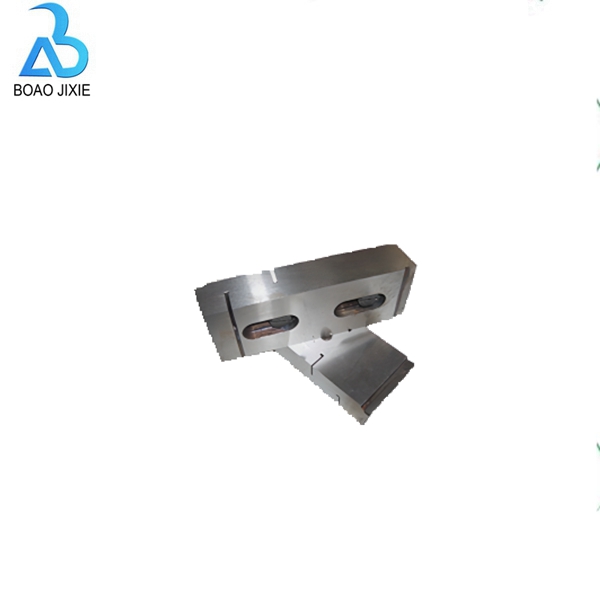

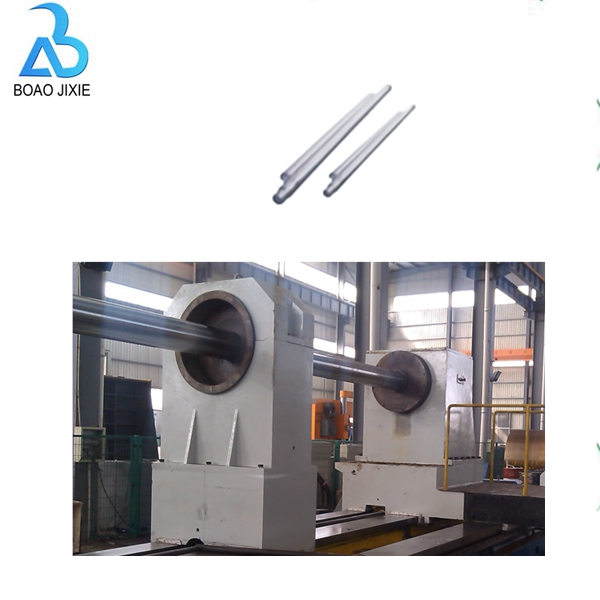

Casing Drilling ntsis kuj yog lub npe hu ua annular laum, nws yog ib qho kev lag luam, tsim tau thiab zoo siab qhov sib sib zog nqus qhov cuab yeej.Nws yog qhov zoo dua los siv casing drilling me ntsis rau machining lub qhov siab tshaj 50mm hauv txoj kab uas hla.Cov cuab yeej no siv tau rau cov xwm txheej hauv qab no:

(1) Qhov txoj kab uas hla yog 50 hli saum toj no, thiab nrog rau kev ua siab ntev ntawm kev ncaj thiab txoj hauj lwm precision

(2) Qhov ntev-rau-inch qhov sib piv ntawm lub qhov yog nyob rau hauv thaj tsam ntawm 1 ~ 75, nws yog qhov kev xaiv zoo dua los siv casing drilling ntsis taub hau dua lwm txoj kev machining.

(3) Cov khoom siv ua haujlwm yog kim heev thiab cov tub ntxhais xav tau kev ntsuas thiab tshuaj ntsuam xyuas, thiab tag nrho cov tub ntxhais mandrel yuav tsum tau tshwj tseg.

(4) Lub tshuab fais fab tsis txaus yog tias drilling lub qhov loj, yog li trepanning yog qhov kev xaiv zoo.Nws yog haum rau txoj kab uas hla ntawm 50 mus rau 600mm (thematching toolbar yuav tsum tau deployed).

| TSIS MUAJ. | Teeb meem | Yog vim li cas | Kev daws |

| 1 | Machining nti me dhau | tsis ncaj ncees txiav cov ntaub ntawv

| Kho ceev thiab pub |

| Tsis raug nti tawg geometry, ellipse lub kaum sab xis me me los yog tob dhau

| Hloov cov cuter slot hom | ||

| Workpiece cov ntaub ntawv instability | Kho ceev thiab pub | ||

| Kev txiav pib tsis zoo (workpiece tsis nruab nrab) | Qhov chaw qhov chaw | ||

| 2 | Machining nti loj dhau | tsis ncaj ncees txiav cov ntaub ntawv | Kho ceev thiab pub |

| Tsis raug nti tawg geometry, ellipse lub kaum sab xis me me los yog tob dhau | Hloov cov cuter slot hom | ||

| 3 | Machining chips tsis zoo ib yam | Cov ntaub ntawv ua haujlwm tsis zoo ib yam | Hloov cov cuter slot hom |

| Txoj kev pub mis tsis raug (hydraulic feeding) | Tshawb xyuas nrog cov chaw tsim khoom | ||

| Kev txias tsis zoo | Ua kom txias dua | ||

| Muaj zog kev co tshwm sim los ntawm tsis txaus rigidity ntawm lub workpiece thiab cov cuab yeej Cov khoom ntawm lub workpiece yog unstable. | Tshawb xyuas nrog cov chaw tsim khoom | ||

| 4 | Fibrous hlau filings | Cov ntaub ntawv ua haujlwm tsis zoo ib yam | Hloov cov cuter slot hom |

| Txoj kev pub mis tsis raug (hydraulic feeding) | Tshawb xyuas nrog cov chaw tsim khoom | ||

| Tsis txaus coolant | Ntxuav coolant | ||

| Tshuaj affinity tshuaj tiv thaiv ntawm workpiece thiab carbide cuab tam | hloov | ||

| chip ntug chipping | hloov | ||

| pub tsawg dhau | Txhim kho kev pub mis | ||

| 5 | Chiping ntawm cemented carbide inserts | Cutter tsis ceev | Hloov |

| Coolant tsis ua haujlwm zoo | Txheeb xyuas qhov ntws thiab siab | ||

| Tsis txaus coolant | Kos lub coolant | ||

| Guide bushing kam rau ua yog me me heev | Hloov | ||

| Drilling bar thiab spindle yog eccentric | Hloov mus rau eccentric | ||

| Tsis ncaj cutter parameter | Hloov | ||

| Cov ntaub ntawv workpiece tsis ruaj khov | Teem kom haum ceev thiab pub mis |